Roving and Top

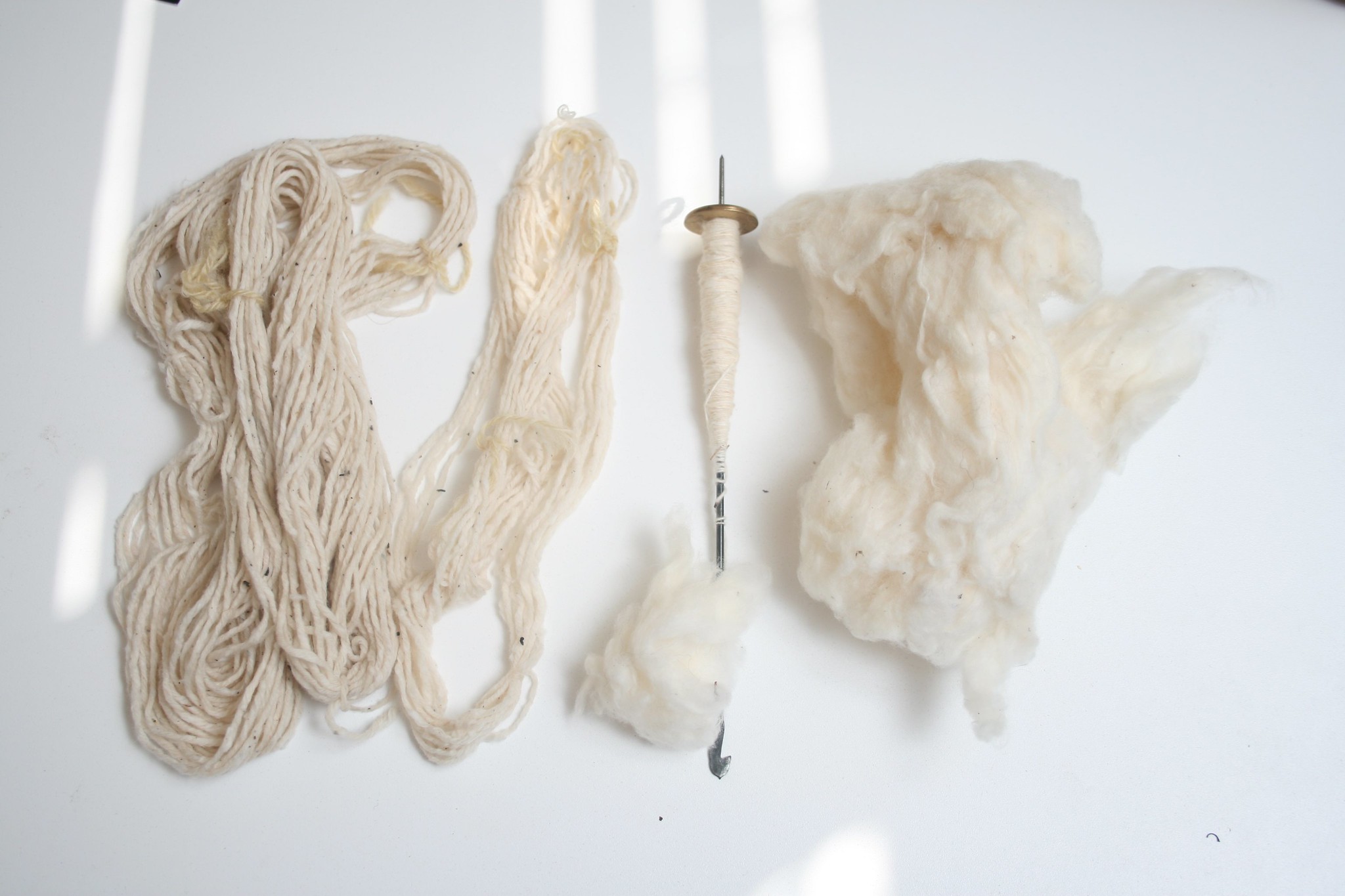

Image Caption: Roving (the form shown on the right) pictured alongside singles and spun yarn on a drop spindle. Credit: Lisa Dusseault on Flickr

Roving and or Top describe fibers that have been given and initial structure to hold them together, but have not yet been given any twist. These are produced by processes of combing or carding individual fibers into into a common direction prior to spinning. Typically, carding fibers entangling them in multiple directions (think a dreadlock). Collections of fibers prepared in this fashion referred to as "woolen" and sold under the name roving. Thus, roving adds a springy and airy quality to a yarn when it is spun. Alternatively, some fibers are prepared through combing (like a pony tail) which aligns the individual fibers in a single direction and often removes fibers of unusual length. Fibers prepared by combing are called "worsted" and sold as top. Worsted preparations tend to produce stronger and denser yarns when they are spun.

There are several products sold on the market such as "carbon roving" or "glass roving" that describe strands of continuous filaments laying mostly parallel to each other. These are structurally very different than roving made from staple fibers but share the quality of being the preparation before twist is added.

Primary Measurements

type: the plant or breed of the combed/carded fiber

staple length: the average staple length of the fibers within the roving (when applicable)

yield: the number of yards of roving per pound.

because roving and top can easily be pulled to cut or twisted back into their structure, the length of the roving/top itself is less important. It assumes people will pull off the amount of roving/top they need at any given time.