An exploration into new mechanisms for jacquard weaving, as well as an ongoing interest in asking how non-human materials or forces can be engaged as collaborators resulted in the prototype of the wind loom—a modified tapestry loom that with every 4th warp connected to a sail that moves the warp position in and out. The fabrication of the loom was led by Jen Mah and Rachel Bork, who iterated between several prototypes for laser-cut heddle/hooks that can be attached to the yarn, arms are connected to umbrellas that can move when the wind blows, easily attachable and detachable components to support easy travel, and so on. The prototyping process was complex and frustrating, as the summer in which we prototyped was not very windy and it was hard to test in its specific working conditions we imagined for the loom. Local weaver, and friend, Julie Rodriguez, took the prototype out for a test and captured the photo above. Her approach was to wait for a gust, and then weave into the wind-produced shed with alternating colors that she chose.

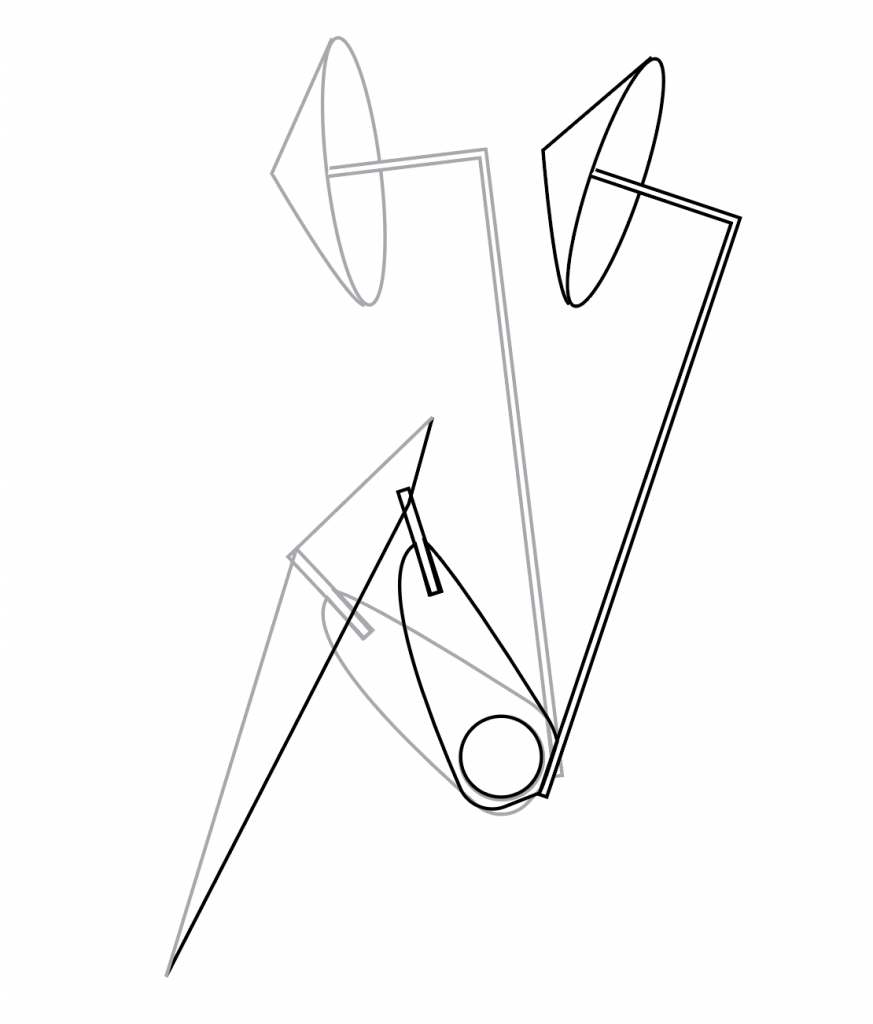

The image above shows a detail of the arm design and how it connects to the warp yarns. First, a small piece of laser-cut acrylic attaches to the yarn. We cut a small “pig tail” in the acrylic to allow the small rectangular joint to be easily wound on and off the warp. That piece then fits into an arm that pivots around a post along the width of the loom. That arm has a long thin aluminum post attached to the back of it, upon which a we attach umbrellas made with nylon and 3D printed attachment joints. The length of the aluminum post determines the speed a which the umbrella will move. The longer the post, the weaker the wind. We found the weakest wind we could capture was roughly 6 mph. We originally had a second 3D printed joint between the metal post and the umbrella post (seen below) but this added to much weakness into the joint and became unruly in a wind gust. All of our part files and instructions can be found on this Instructables post: https://www.instructables.com/id/Wind-Loom/

The view of the loom during development. We staggered the umbrella height in order to activate certain warps at certain speeds and to also make sure all of the umbrellas could fit into the space.

To prevent the arms from moving in directions not along the direction of the wind, we had to fabricate supporting “tracks” out of acrylic. These held the arms in place without inhibiting their movement (as we found with packing spaces with metal rings.). To help someone easily assemble and disassemble and travel with the loom, we made this track fixed by magnets, which worked well to hold it in place.

The insights from this is that the machine for weaving with the wind is incredibly frustrating to use. Mostly because the whole apparatus is large and the design of the umbrellas only catches wind traveling in one direction. While I initially considered redesigning to a smaller form, and reworking the umbrella design, I enjoy the idea of this machine being one that invites frustration. If the goal is to collaborate with an uncertain and unpredictable force, maybe frustration is precisely what ought to occur. Maybe it helps us confront our own limitations.