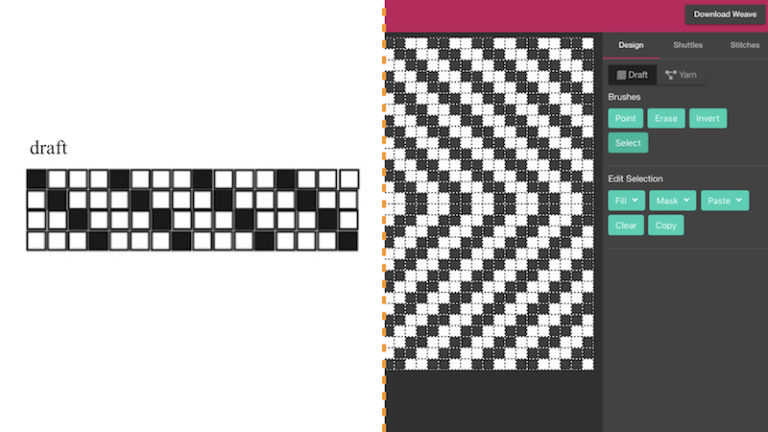

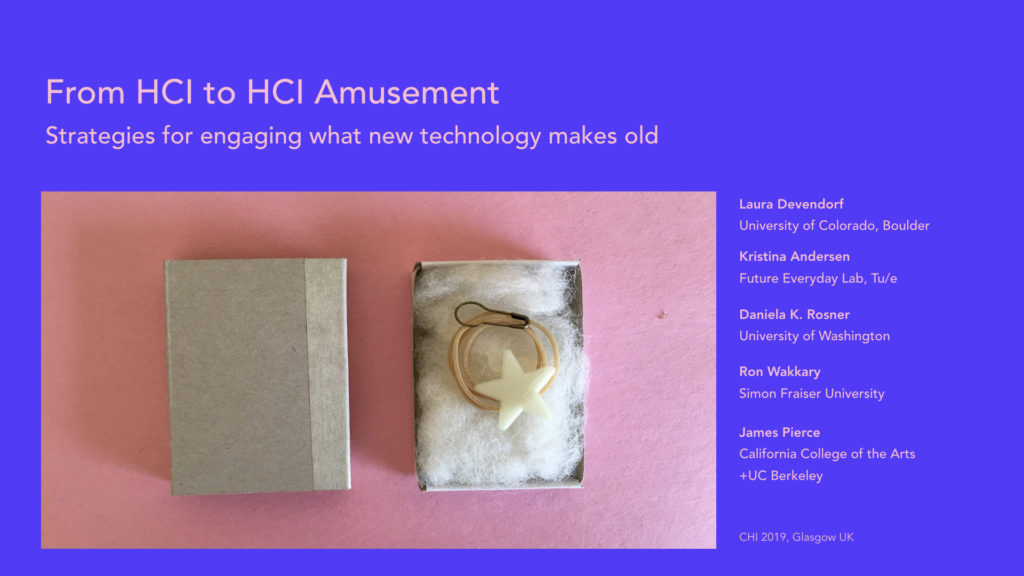

Laura Devendorf and Sasha de Koninck are designing a new course to be offered in Fall 2020, Soft Object. The course will cultivate a community of material researchers seeking to make soft things that expand how we think of interactivity. While starting with soft circuits, the class will support material investigations with novel techniques for textile structure, growth, computation and decomposition. Students will learn about different soft material structures, properties, and possibilities. As a course, we will develop, refine, and publish novel techniques for smart/functional fabrics in the form of a physical and open source digital “swatch book.” Students we will think about the history and future of textile and soft-object making, while conducting their own material investigations.

We are designing the course to run mostly virtually. If you are a CU grad student or undergraduate student, please join us. If you are an interested global community member, please get in touch with us via unstabledesignlab@gmail.com as we may look to develop a forum for public engagement and critique.

ATLS 4519/5519: Soft Objects

Monday/Wednesday 3:00-4:40

ATLAS 113 – Blow Things Up Lab

Official Listings: ATLS 4519 //ATLS 5519