Industrial/Jacquard Loom Weaving #

Jacquard Looms #

A jacquard-style loom is one where every heddle can be individually controlled. Originally, they were selected by punch cards (which inspired the earliest forms of computing) and today, they are computer controlled with small motors, electromagnets, and or pneumatics. Jacquard style looms fix the position of each heddle, so they typically have a set density they will weave. Jacquard style looms are best for creating non-repeating patterns and more complex woven structures. Most consumer obtainable jacquard looms still require the weaver to remain present at the loom while weaving and to throw the weft yarn (held on a shuttle) between the ends of the fabric.

Industrial Weaving #

While the looms listed above are common in prototyping and developing and testing structures, Industrial looms produce most woven fabrics on earth today. These looms include mechanisms (such as a “rapier mechanism”) that automatically pass the weft yarns through the shed without any human involvement. These machines are incredibly fast and have very high epi’s. I have no idea how they warp these machines but it must be wild.

TC2 Loom #

TC2 Loom Anatomy

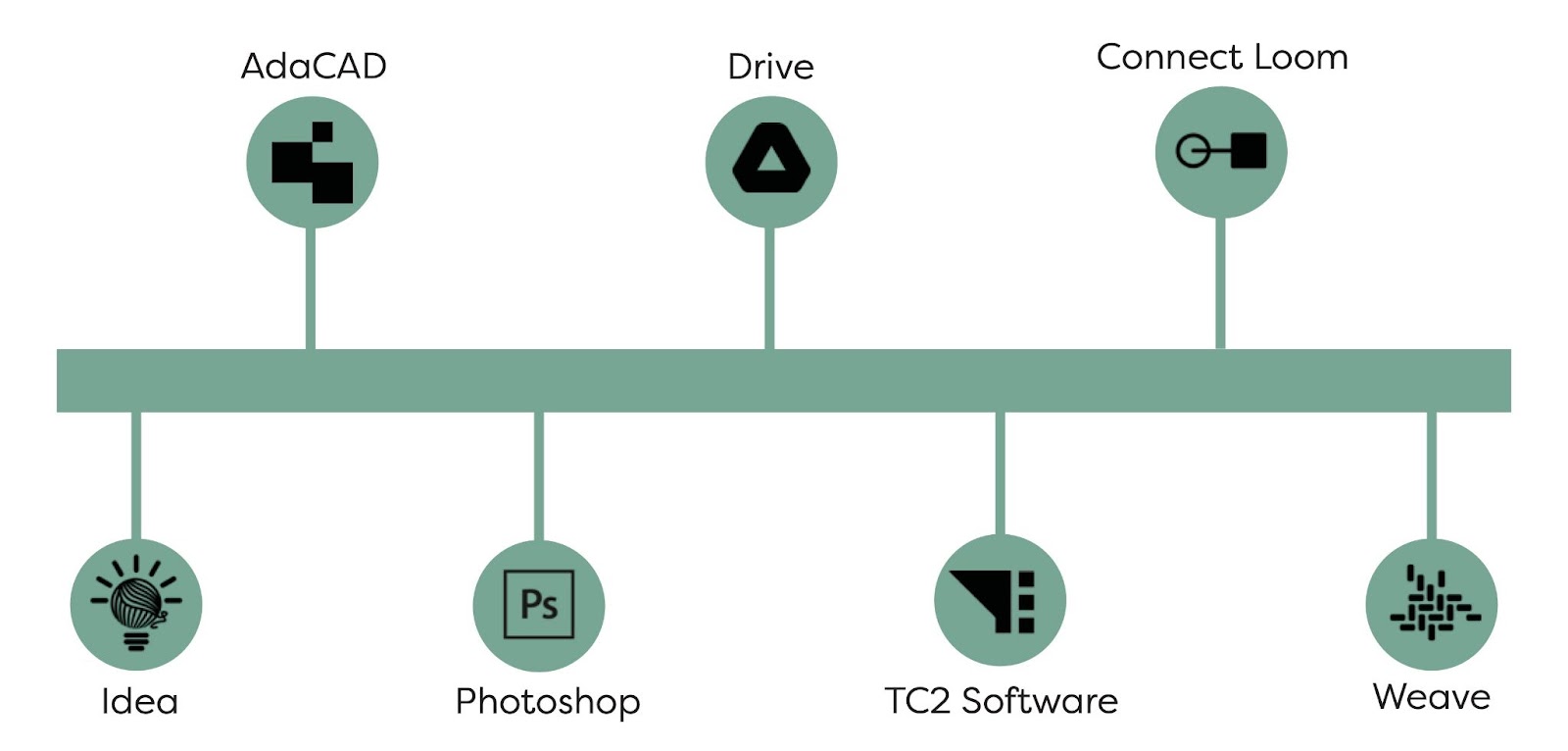

TC2 Process Overview

Idea Generation TODO

Adacad TODO

Photoshop TODO

Drive TODO

TC2 Software TODO

Weave TODO